Hygiene and Sanitation on the Food Manufacturing Industry

No matter how clean any production facility may look like from the outside, it could never be an assurance that it is safe from microbiological and chemical contaminants. In the manufacturing industry, it is necessary that hygiene and sanitation programs are in place and practiced by everyone.

Designing an effective hygiene and sanitation program depends on the equipment and nature of products and materials used. However, regardless of the specifications and methods of cleaning employed, the primary objective of hygiene and sanitation is to ensure that the quality and safety of food products are being maintained throughout the production process. If the cleaning method employed is insufficient, pathogens and allergens lurking in the environment, especially on improperly cleaned food contact surfaces, may compromise food safety and may result to food recalls. Food recalls affect manufacturers negatively; they would have to endure immediate, direct costs, compliance penalties, lawsuits and litigation, lost sales, and brand deterioration.

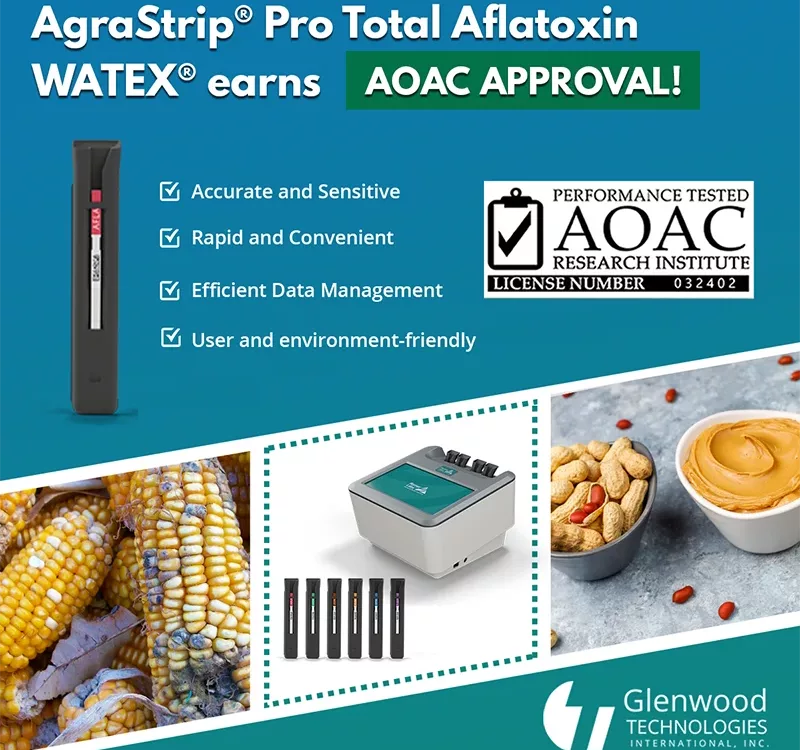

This can be avoided by utilizing technologically-advanced hygiene and sanitation verification testing tools. Hygiene and sanitation will always be a key component of an effective food safety management system, and must be given utmost priority by food producing facilities.

#FoodSafety

#FoodSafetyAwareness

#FoodSafetyPhilippines

#FoodSafetyPH

#FoodSafetyBites

#FoodSafetyLifeMatters

#FoodSafetyTrendsPHMagazine

#FSTM

#GlenwoodTechnologies

#Glenwood